Hornberger Avenue & Second Avenue, Roebling, NJ | View Map

John A. Roebling (1806-1869) was a German born engineer and inventor who helped design and construct some of the country’s landmark suspension bridges. One of Roebling’s most important innovations was the wire rope he developed as a substitute for the massive hemp ropes used in haulage and construction. This new wire rope was durable and flexible and quickly became a valuable new engineering material. Roebling became famous for his inventive use of this new material in suspension bridges. In 1845, he built the suspension bridge across the Monongahela River at Pittsburgh, and he designed a nationally acclaimed railroad suspension bridge (completed 1855) across the gorge of the Niagara River. His best-known project is the Brooklyn Bridge, which he designed with his son Washington Roebling. The Brooklyn Bridge opened to traffic in 1883 and was the world’s longest suspension bridge at the time of its construction.

In 1848, Roebling established a simple wire rope making facility in Trenton that became the city’s largest employer and one of New Jersey’s most famous industries, the John A Roebling’s Sons Company. At its height, the Roebling works consisted of four plants, with 258 buildings covering 4.5 million square feet.

The Kinkora Venture

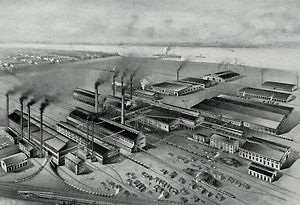

Kinkora Works, c.1912. Credit: Special Collections and University Archives, Rutgers University Libraries

The Kinkora Works represented a new chapter in Roebling entrepreneurship. By 1900, the company needed to expand operations to meet demand for its growing product lines. In 1904, the company decided to make the largest capital investment in its history and build its own steel plant and new wire production facilities. The size of the plant required a large open site close to the main plant in Trenton and with access to railroads and water. The company found a large parcel of farmland with frontage along the Delaware River near Kinkora, a railway village some ten miles from Trenton headquarters.

More than a million cubic feet of earth was cleared for the site and construction began in 1905. Charles G. Roebling (1849-1918), president of the company, designed the state of the art manufacturing facilities and equipment as well as a model town for Kinkora workers and their families adjacent to the plant. Roebling trained as an engineer and had excellent business instincts. Under his leadership, the company added two more mills and more than 8,000 employees. With the able assistance of his brother Ferdinand, Charles Roebling introduced many production innovations, expanded product lines and increased sales revenue dramatically.

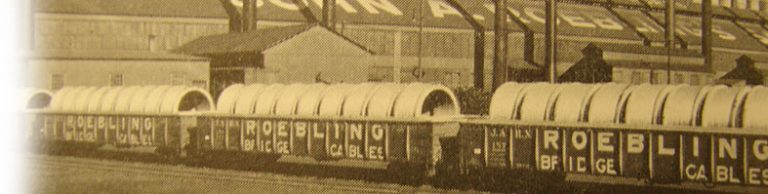

The 200-acre Kinkora plant represented a bold new business strategy. The new Kinkora mills allowed the company to create its own supply of the high quality steel needed for its wire products. The new steel plant included nine open-hearth furnaces; the famous blue center steel was made here for the company’s wire rope. The Kinkora Works was designed for maximum efficiency and had several specialized facilities: blooming mill, rod mills, cleaning houses, wire mills, annealing and tempering departments, galvanizing shop, copper mill, and a plant where woven wire fabrics were manufactured.

The additional manufacturing capacity provided by the Kinkora Works allowed the company to keep pace with technological advances requiring wire products such as elevators, aircraft and electrical transmission. Wire produced at Kinkora was also used for such defense materials as submarine nets and ocean mines. Kinkora’s workers manufactured the wire used in the Golden Gate and George Washington Bridges and the control cables in the Spirit of St. Louis, the first airplane to cross the Atlantic. To meet increased demand for its wire products, the company doubled the size of its mill and support shops within the first twenty years.

Roebling employees at George Washington Bridge. Credit: The Blue Center, Trentoniana Collection, Trenton Public Library

The Roebling Company sold the steel mill in 1952 to Colorado Fuel and Iron Inc. By 1974, when the plant was closed for good, there were 70 buildings on the site. In the 1980s, the Federal Environmental Protection Agency determined that the abandoned plant was a threat to public health and an environmental hazard. The buildings contained toxic materials and the groundwater under the site and nearby waterways were contaminated. The Roebling Steel Company site, as it was known, was added to the Federal government’s national priority list of polluted sites, known as “Superfund” sites in 1983.

The lengthy clean up and remediation of the site began in 1985. Work has involved removing hazardous materials above and below ground, decontaminating and demolishing buildings, and removing and treating and contaminated soils. Measures were taken to contain existing contaminants and protect ground water supplies.

As part of the remediation work, two of the plant’s original structures have been preserved and adapted for new uses. The distinctive gatehouse at the plant entrance and the ambulance garage house historical collections and a museum focused on the history of Roebling village. Local and county governments are working to find suitable redevelopment plans for the site.

For more information:

- www.roeblingmuseum.org

- www.capitalcentury.com/1905.html

- www.sitesofnj.com/Roeblingsteel.html

- www.burlingtoncountyhistoricalsociety.org

- memory.loc.gov/ammem/collections/habs_haer/index.html

- www.njtransit.com

Banner credit: The Blue Center, Trentoniana Collection, Trenton Public Library